Week 2: Computer-Aided Design (Solidworks)

Introducing parametric modelling.

Background information on CAD

Watch the corresponding Fab Academy lecture. We’ll be covering part of this content.

- Fab Academy lecture notes: http://academy.cba.mit.edu/classes/computer_design/index.html

- Lecture from 2019

Baseline

Who has:

- Used CAD software

- Used parametric software

- Produced 2D drawings

Solidworks (PC only)

is…

- Parametric: everything is driven/adjusted by numbers (length, diameter, thickness, colour, etc).

- Feature-based: geometry is created with features

- Associative: parts, assembles, drawings are linked - a change in one will filter to all

SW can do: FEA, CFD, motion analysis, electronic wiring, lots more!

Student licences- £6 for a USB from computer store, 1st Floor Watts Building. Renew at the start of each academic year.

Certification exams: we will provide these: TBA

Resources:

- Start with these…..Help menu > tutorials (Lesson1: parts, Lesson2: Assembles, Lesson3: drawings) - these are excellent, make notes, observe everything and master them.

- lesson 1: parts video, and here is the part to download

- lesson 2: assemblies video, and here is a .zip file with the assembly to download

- lesson 3: drawings video

- use the help (online also)

- Grabcad/Thingyverse/etc (filter for Solidworks models).

- any existing models to reverse engineer

- Lynda.com (for UoB: www.brighton.ac.uk/lynda) - Solidworks 20XX essentials.

- sketching exercises

- part modelling exercises

Layout:

Units: see bottom right hand corner (use millimeters!)

Navigation:

MIDDLE DOES EVERYTHING!

- zoom: scroll middle

- rotate: hold middle

- pan: hold middle + CTRL

File types:

- Parts: as it would be manufactured, and here is an example part to download

- Assemblies: a collection of parts (and/or of other sub-assemblies), and here is a .zip file with parts and an assembly file

- Drawings: orthographic of parts (with dimensions) and assemblies (with NO dimensions, with balloons + bill of materials (BOM))….or both.

difference between Fusion 360 and Solidworks

Basic part modelling process:

- Create new sketch

- Select plane or flat surface to sketch on

- Draw 2D sketch (open or closed)

- Exit sketch

- Use sketch to create feature

Follow these steps, be methodical

Sketch entities: (note different options for each)

- line

- arc

- rectangle

- circle

- spline (avoid where possible)

- use smart dimensions ALWAYS

- toggle construction lines on/off

Sketch tools:

- convert entities

- offset entities

- trim (oh power trim!!)

- mirror/pattern

Sketch relations:

- coincident

- concentric

- equal

- parallel

- perpendicular

- colinear

- coradial

Basic features:

- extrude/cut

- revolve/cut

- hole wizard Intermediate features:

- sweep/cut

- loft/cut

- pattern

- mirror

Early part challenge:

- create a 6-sided die (10x10x10mm, R1mm fillets on all faces, D2mm holes 0.5mm deep (opposing sides add up to 7)

- all details must be dimensioned fully

- approach this in different ways, aim to do it as fast as you can

- record < 1min, excellent < 5min, ok < 15min

- 2019 leaderboard

- example die part file to download

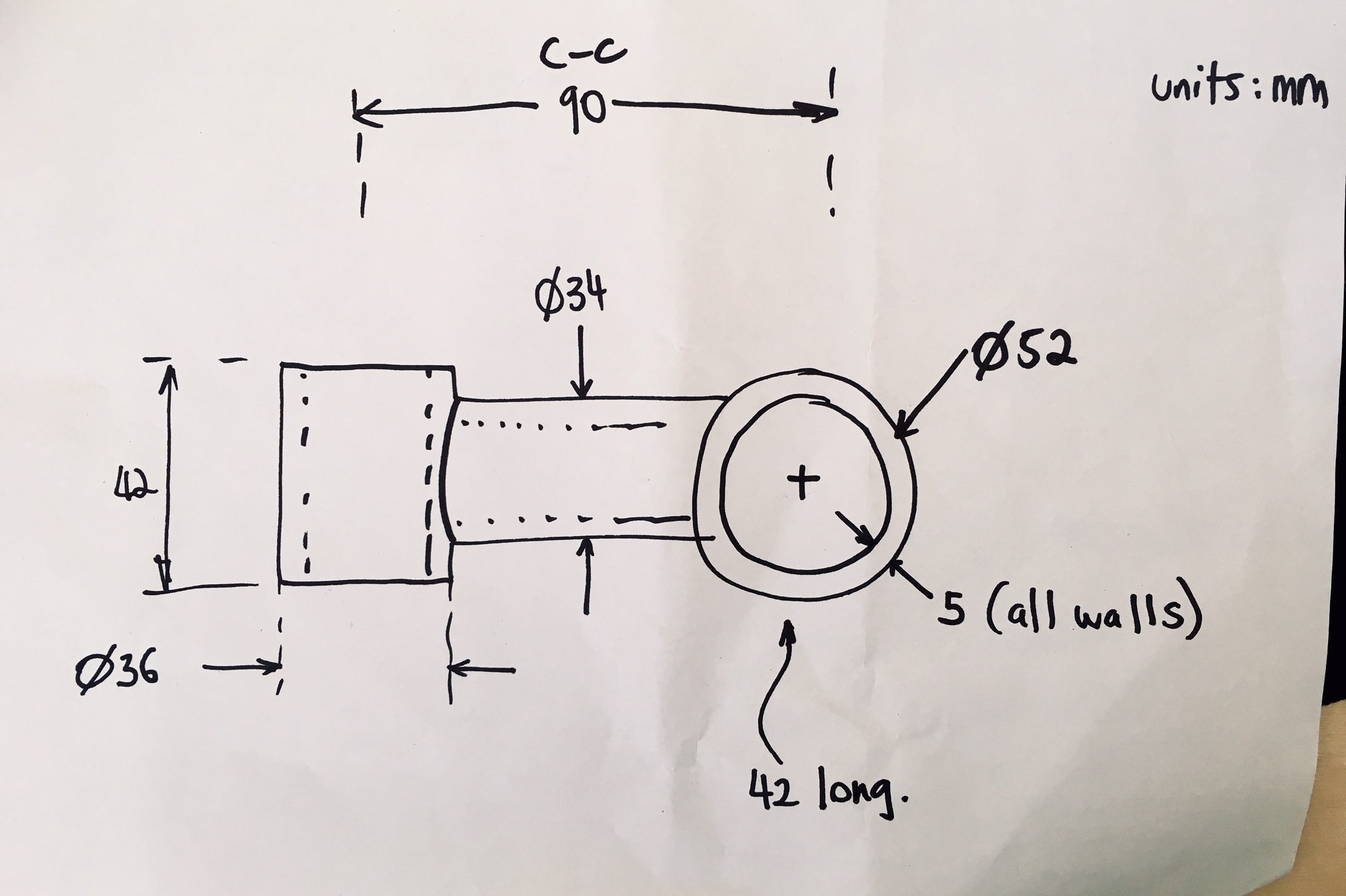

Second part challenge:

- create a bicycle stem using extrude/cut, fillets. You don’t need to create extra planes, but you can if you wish.

- this is an exercise in understanding how to use your reference geometry (planes) well - it is quite a spacial awareness challenge!

- here is a completed version with all the trimmings

- start with the three basic cylinders, then add details after.

- for an extra challenge, angle the head tube (vertical tube) by 7 degrees to the horizontal

Useful tools:

- toolbox (nuts, bolts, gears etc)

- Traceparts CAD models

- also Grabcad/Thingyverse/etc

Assemblies

- can mate: vertices, lines/centrelines, faces, planes

- coincident, offset, parallel, concentric etc

- standard mates

- advanced mates: limits

- mechanical mate: gears

- mechanical mate: cams

- mechanical mate: belt+pully

- exploded and collapsed views

- animations: rotate, explode, collapse

Assembly challenge

- download this .zip folder and unzip it

- open the “plunger.asm” assembly file

- look at how the parts move

- here is an assembly drawing to act as a guide

- the challenge: recreate this assembly in a new assembly file. Create an exploded view and animate the explode/collapse.

- bonus: position the link plunger so that it is 15degrees to the horizontal. This will lock the assembly so it won’t move.

Drawings

Rules

- make it clear!

- use only enough views as are necessary

- don’t duplicate dimensions

- make dimensions measurable (using ruler, calipers, micrometer etc)

- don’t cross dimensions

- space dimensions consistently

- don’t place dimensions on a part

- make sure the title block is complete

- use sans serif fonts only (ideally use CAPS)

Tutorial

- Help menu > tutorials (Lesson3: drawings)

- lesson 3: drawings video

- advanced tutorials: - Help menu > tutorials (all) > Advanced drawings (a.Drawing views, b. Detailing, c. Assembly Drawing views)

-

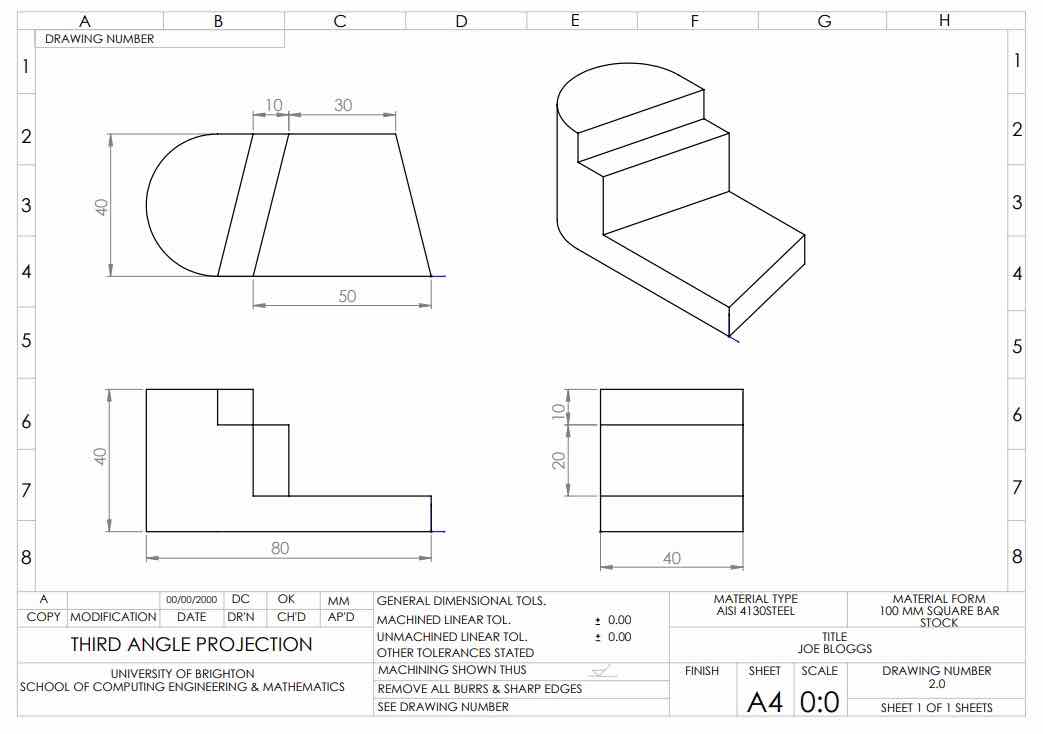

orthographic drawings of parts (with dimensions). Note that there should be sufficient detail and dimensions for the part to be manufactured. Drawings should be checked by others.

-

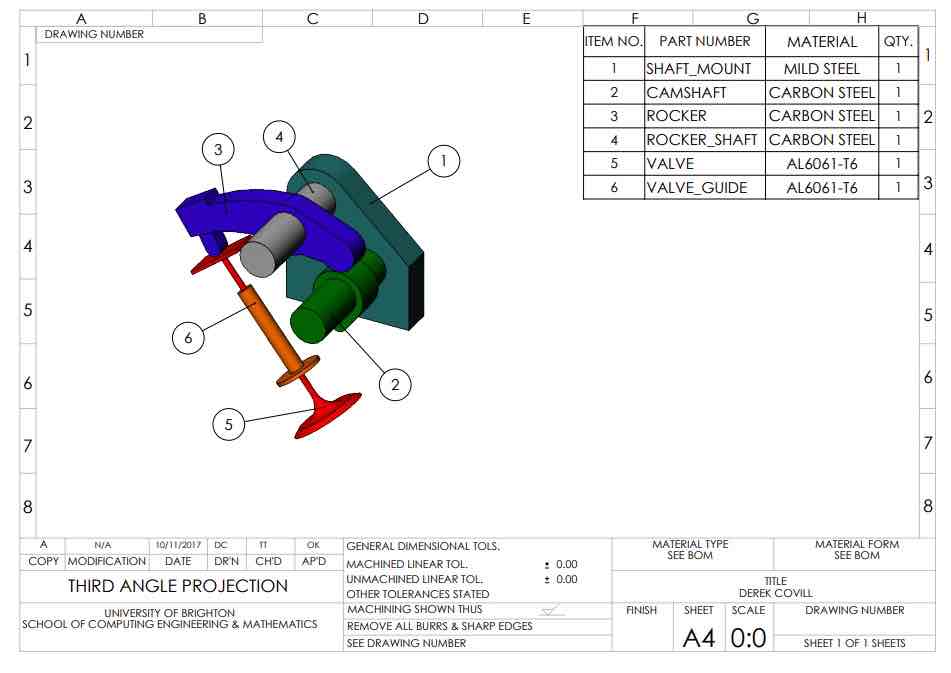

assembly drawings have NO dimensions, but they do have balloons and include bill of materials (BOM)

- you can also combine both types of drawings into a single drawing, but this is not advised. both-part-assembly-drw-combined.

- introduction to technical drawing

- types of views

- BS 8888:2017 –Technical product documentation and specification

- include appropriate tolerances simple tolerances drw

- base tolerances on manufacturing capability charts

- limits and fits tolerances for holes and shafts

- use the solidworks A4 drawing template

- 1st (roll) or 3rd (slide) angle projection video

Part drawing challenge

- here are some good exercises to help understand technical drawings

- pick one of these, create the part then create a complete drawing for this part (assume one square = 10mm)

- use the template provided above

- include all dimensions required to make the part

- include a complete title block

- assume that it is machined using a CNC milling machine and then specify the appropriate tolerances using the manufacturing process capability charts above

Assembly drawing challenge

- find an interesting assembly in GrabCAD (make sure it’s a Solidworks assembly!) and download it

- unzip the folder with all the files

- make a complete assembly drawing of the main assembly

- use the template provided above

- include a complete title block

- include baloons for all parts

- include a complete/appropriate BOM (note that you may need to make adjustments to part names or other details)

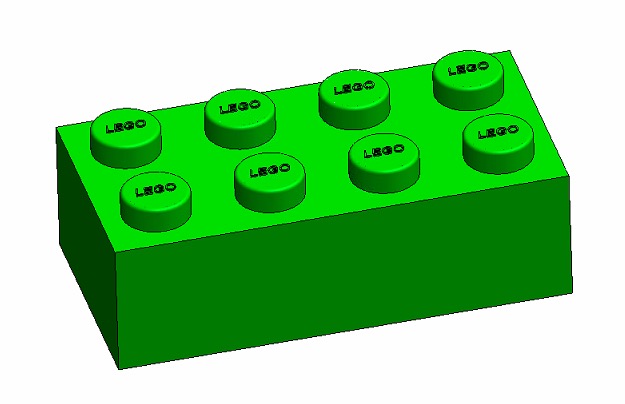

Advanced part drawing challenge for homework

- Lego part challenge: download the lego solidworks part here

- create a part drawing of this lego brick

- use the template provided above

- include all dimensions required to make the part

- include a complete title block

- note the requirements for this to be a

- assume that it is injection moulded from ABS and then specify the appropriate tolerances using the manufacturing process capability charts above

- assume that the bosses of the lego brick need to be a ‘press fit’ with the underside of the next brick, using a H7/p6 tolerance which assumes H7 (hole) tolerance range = +0.000 mm to +0.025 mm, and p6 (shaft) tolerance range = +0.042 mm to +0.026 mm

- note…this is challenging :0)

More features in Solidworks

- features: extrude, hole wizard, mirror, pattern, shell, fillet, revolve, sweep, loft, split

- reamer part with many features

- Help menu > tutorials (All) > Revolves and Sweeps, Lofts, Patterns, Fillets)

Solidworks part features exam! (1 hour)

- Make a donut (overall diameter 100mm, section diameter 20mm) using a revolve (10 marks)

- Put a M5 countersunk hole through the donut (in axial direction) (5 marks)

- Pattern this hole so that there are 5 of them spaced around the donut (5 marks)

- Take a measurement of the cross sectional area of one cut through the donut where an M5 hole is (5 marks)

- In the same part make the same donut (no holes this time) again using a sweep (position it next to the existing feature) (10 marks)

- Now make it using a loft! Again, position it next to the existing parts (15 marks)

- Score out of 50? (Pass >= 25, merit >=35, distinction >= 45)

- here’s the finished part with the donuts!

- here’s the section view results

3D sketching in solidworks

- first a little warmup! let’s make this 2D sketch, and then make this solid part

- if you like that sketching exercise, here is 99 more!

- until now we’ve avoided 3D sketches because they can limit the ability to do features (e.g. revolve, loft)

- but they can also open up new ways to create geometry

- they work by creating a sketch that moves between sketching planes (e.g xy, yz, xz and any planes parallel to them) - and this is done by pressing TAB

- you can then draw lines in and out of these planes as we’ll see in this example

- 3d-sketched-rack-part

- this example is also done as part of the tutorial in Help menu > tutorials > 3d sketching